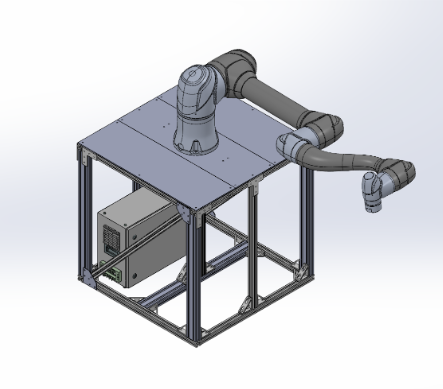

Doosan H2515 Base

First big project in the PROOF Lab, I was tasked with building a base for the robot to be mounted on. Made from 8020 extrusions, calculations made with the maximum payload in mind to ensure that the robot would not tip over from use over edge. Constructed base and supervised installation of it onto the robot.

Skills: SolidWorks, FBD Calculations, Machining

Obtained an STL model of the robot, which helped with creating the base. Custom plates needed to be designed to create the angular truss which prevented twist and kept the frame square. Over 200 screws were used in assembly, and the plates were machined by me in the machine shop. I also drilled holes in the top plates to accept screws into the 8020s. THe power supply was fitted underneath the base, and weights were added on the base in the form of 45lb gym plates.

Gold Nanoparticle Research

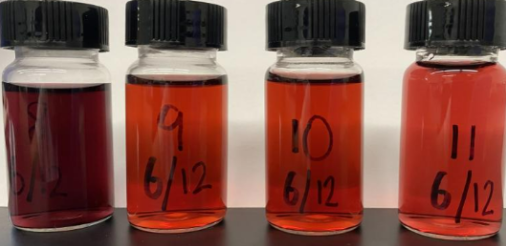

Developed Labs for the E311 course at Stevens, a materials processing course taught under Prof. Sarah Goodman. I created Gold Nanoparticles using the Turkevich method and adjusted the size through adjusting the concentration of sodium citrate solution. Resulted in nanoparticles of different sizes, which because of refractive properties changed the color of solution. Implemented at a cost of under 1 dollar per student. I presented my findings at the ASEE MAS Fall 2023 Conference.

Skills: Scanning Electron Microscopy, Spectrophotometry, Molarity Calculations

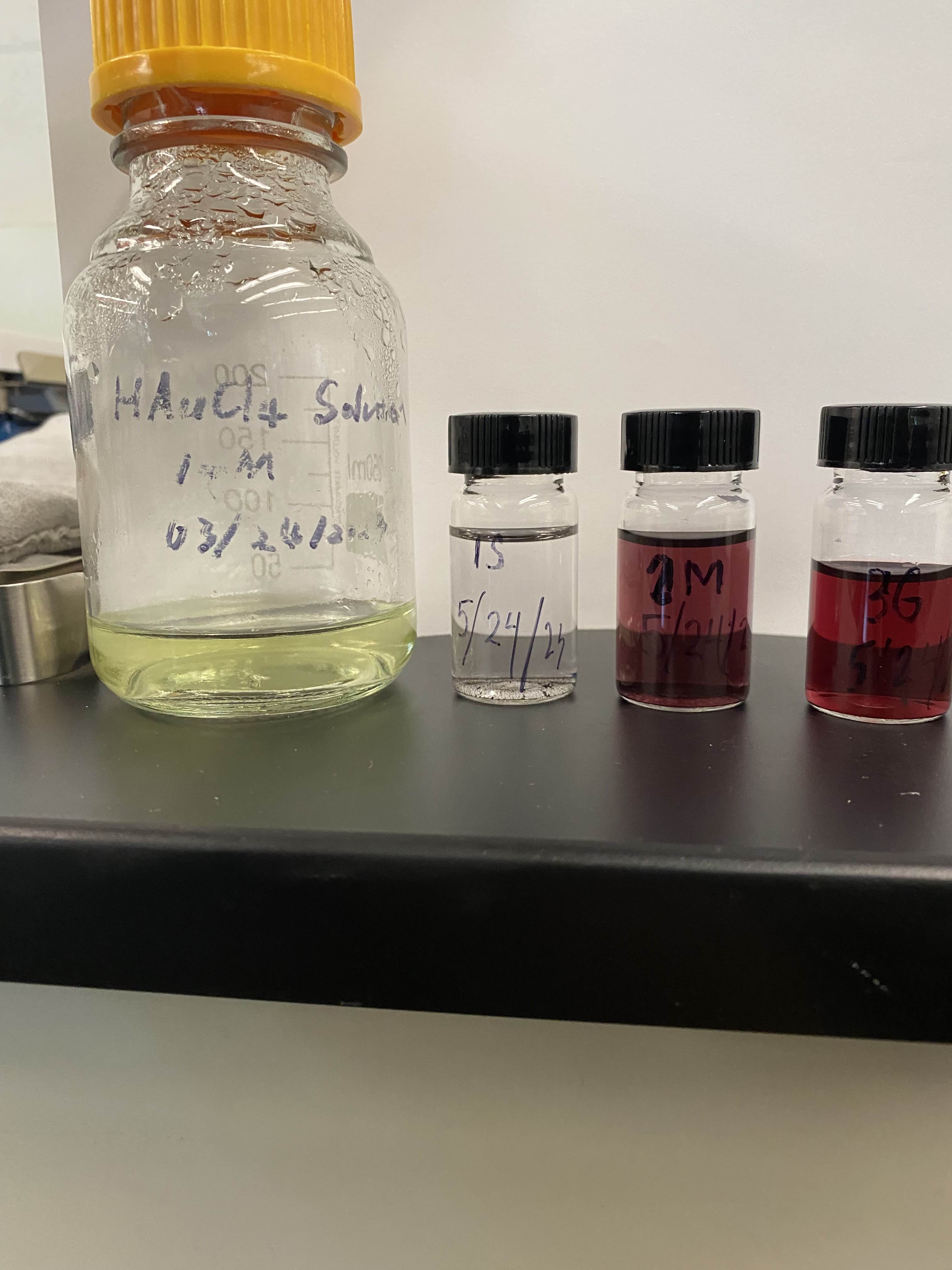

Gold (III) chloride is diluted using distilled water. When constantly stirred with diluted sodium citrate under heat, the solution turns from yellow to gray, then to red or purple, which indicates the formation of these nanoparticles. The heat and duration of mixing were changed and tested for observable diffrences in color or size. Best results were with changing the concentration of sodium citrate, which yielded a difference in about 50nm.

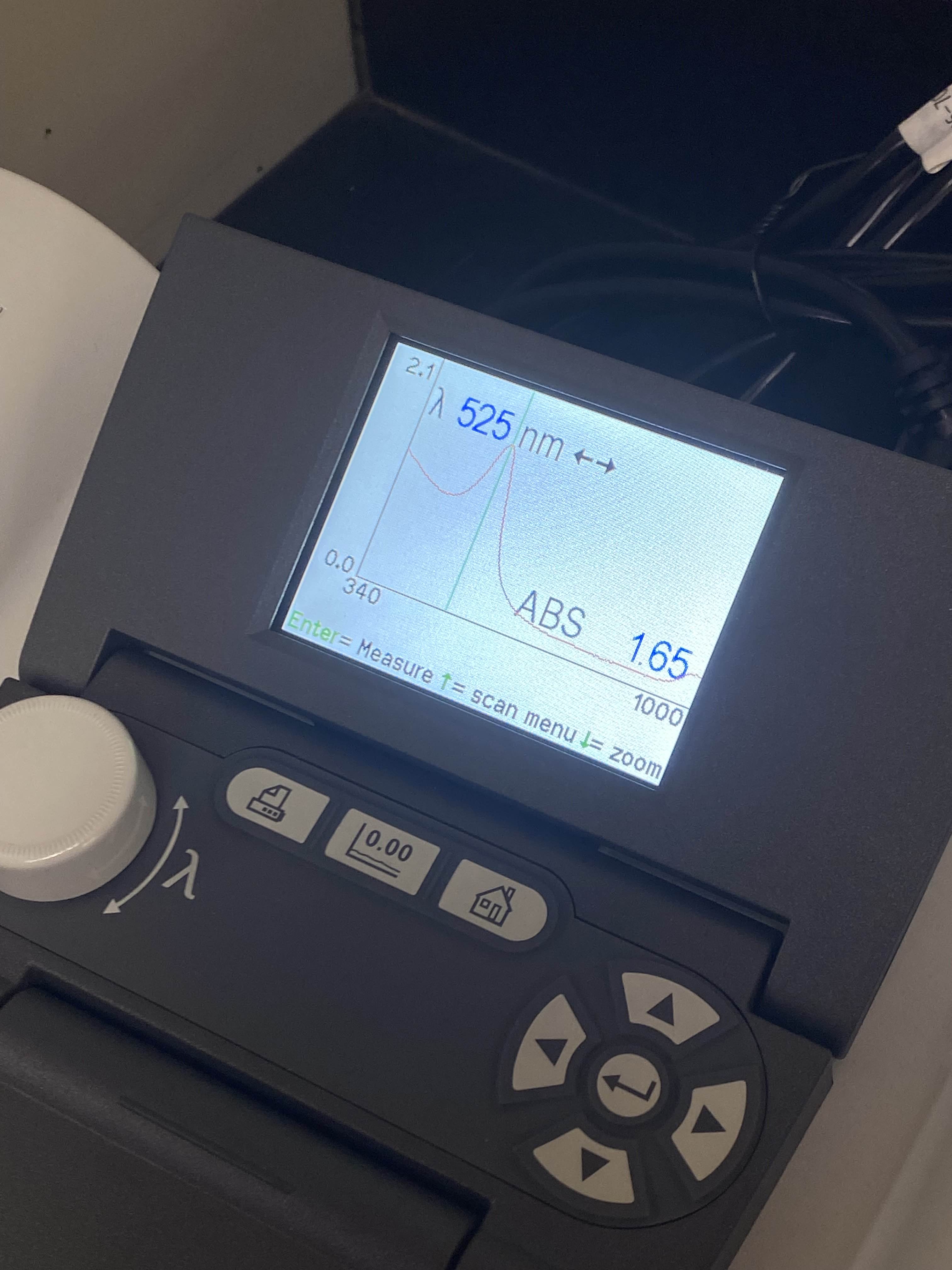

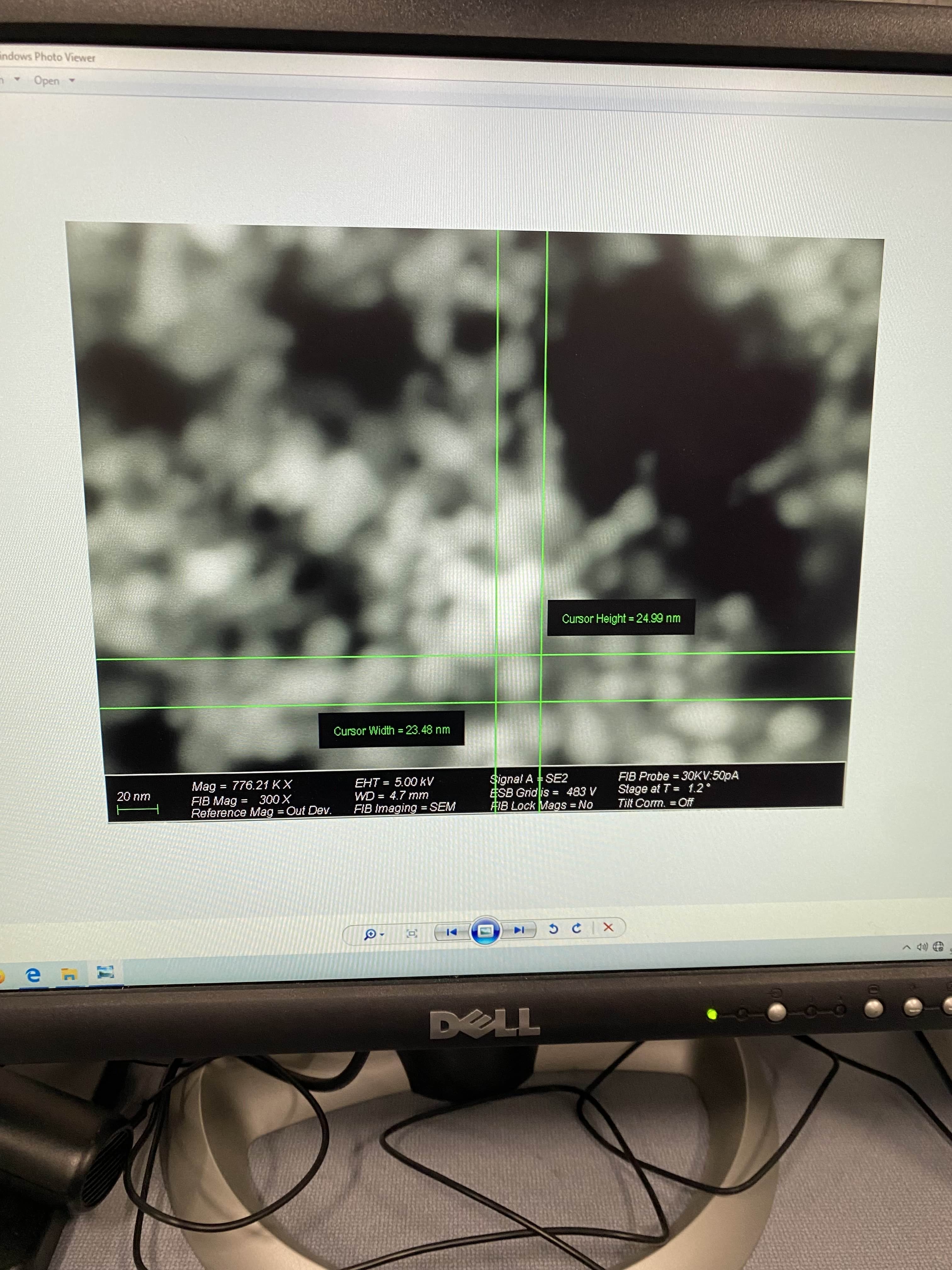

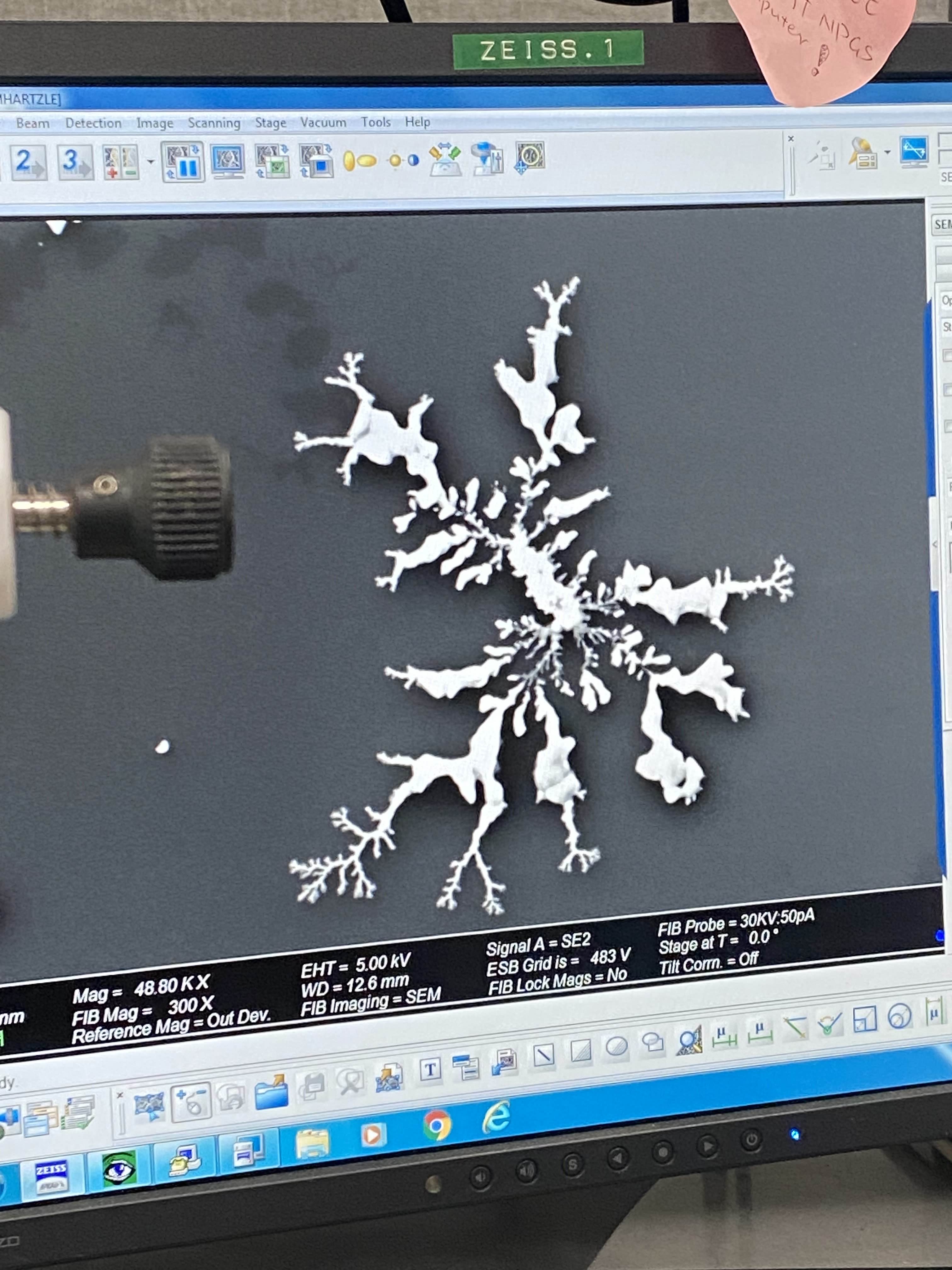

The sizes were tested and confirmed with a Scanning Electron Microscope, which I was trained to use. Samples needed to be pipetted onto a SEM stand with a silicon wafer, and dried properly. The samples were then observed under the SEM. The color of the solution was also quantified using Spectrophotometry, which outputs a wavelength of color. These findings were enough to establish a relationship between concentration and size.

Kumiko Lamp

Needed a study lamp for my room. Made from basswood and walnut, light is diffused through shoji paper lined on the Kumiko panels. Lamp designed so that if panels are broken, they can be detached, serviced, and replaced.

Skills: Hand-Tool Woodworking, Patience

I started off with watching videos for inspiration, then sketching ideas out for the kumiko panels. This was a major quarantine project. Power tools seemed a bit intimidating and extremely wasteful when making Kumiko, as the kerf from a table saw blade rivals the thickness of a single Kumiko strip. I resorted to hand cutting and planing each piece down to size, and gluing up all the joints.

Spray adhesive was applied to the back to accept the shoji paper, which was carefully laid onto the kumiko and allowed to dry. Dabs of hot glue secure the panels onto the walnut frame, for easy replacability in case a panel breaks.

Watch Box

Created a watch box using walnut and poplar. The edges of the box are dovetailed with a miter on the bottom to disguise a slot routed for the bottom panel. Box designed to hold 6 watches comfortably, poplar was chosen as inner liner for its softer properties.

Skills: Hand-Tool Woodworking

Hardest part was doing the mitered dovetails on each of the corners, but they came out pretty nice.

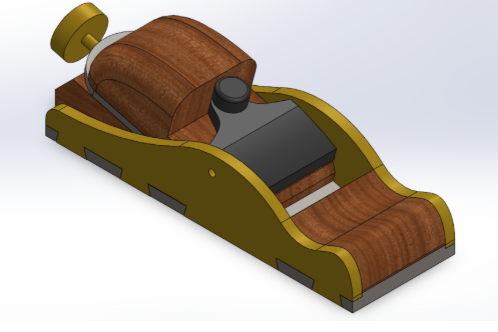

Infill Block Plane for Woodworking

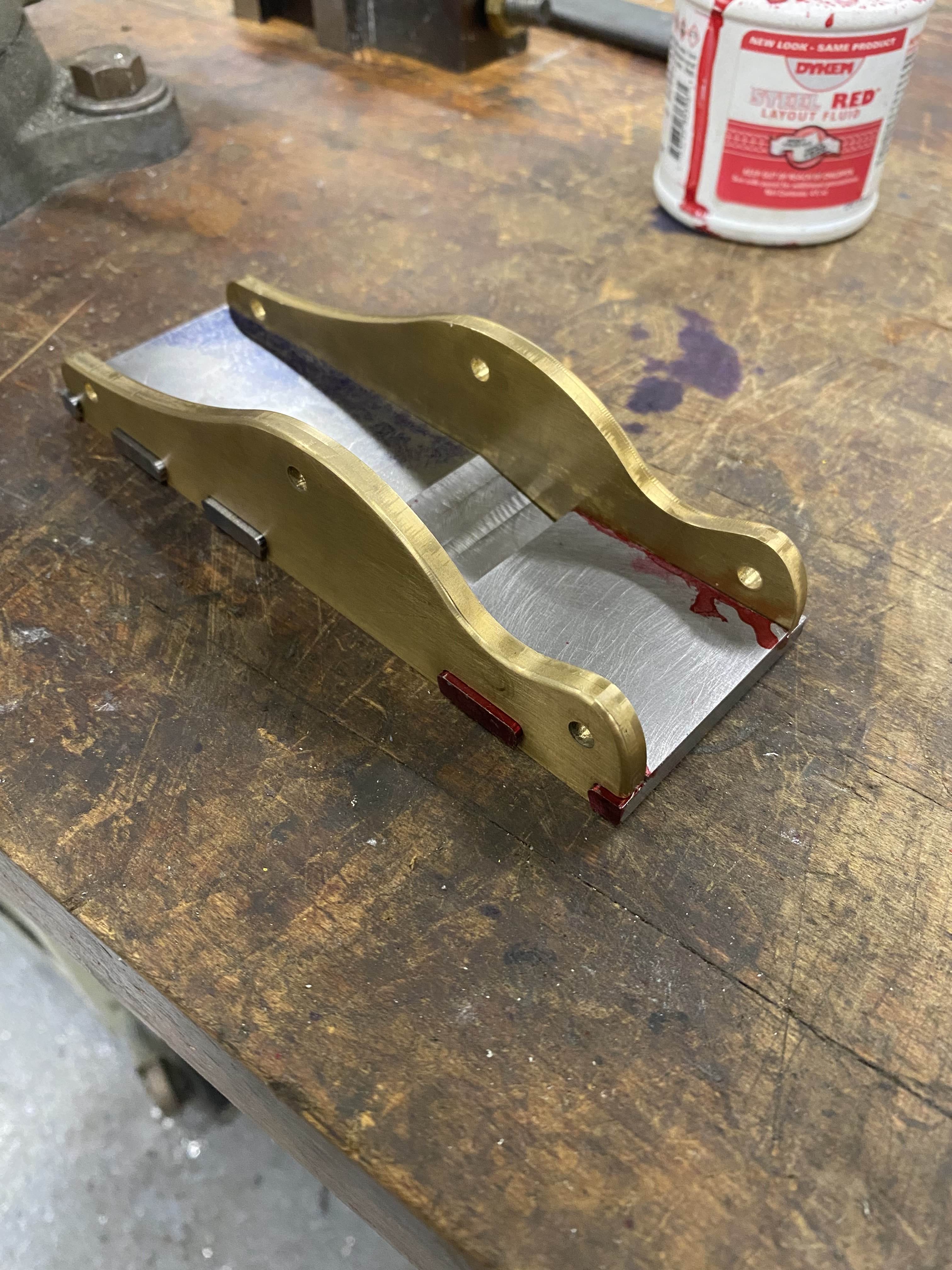

I wanted to create a block plane using brass and steel for my woodworking projects. The machine shop at Stevens taught me how to run the manual CNC machines, write programs for them and run them autonomously. I designed the programs to carve out rounded dovetails, and machined components.

Skills: CAD, CNC and manual machining

Project is still a WIP until I have the courage to bring a hammer to the dovetails to make them permanent. Progress pictures can be seen below. All components are separate, but about a month of hard work and learning went into machining the body so I am a bit hesitant to make the connections permanent in case something goes wrong. I also still need to find or make a blade for the plane, as my custom width plane is more narrow than other blades and will require a custom one to be made and heat treated to retain a sharp edge.

VGEORGE

Virtually Generated Engineered Organic Realistic George E-assistant (haha). I followed a YouTube tutorial on creating a home assistant using AI and modified the code for my needs. A neural network with natural language processing (NLP) was coded which can process vocal commands and map to certain functions. A YAML file holds all the inputs, then get mapped to certain outputs. These outputs could be functions which further break down the input, such as a weather API to return a default temperature you can set, or if you'd like a certain area can return the forecast of a specified location.

Skills: PyTorch, NLP, API Calls, Python

Links: GitHub

Modules I created include the weather API, a random number generator, a timer, and a google search feature. I used google text to speech to make the voice sound less robotic. If I were to redo this project, I would add more generalizability deeper into the layers, and add more custom apps like notetaking and the ability to add to a calendar and notify the user of events.

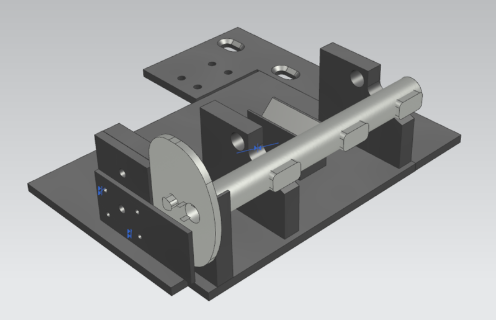

Fixture for Securing Castings - Zimmer Biomet

Cutting operations for machine operators was manual, creating a dangerous work environment. Fixture was designed in Siemens NX and constructed from steel. GD&T principles employed for drawings; machinists were super helpful in guiding me through machining tolerances. Final fixture deployed on floor, safely securing tibial casting and resulting in hands-free operation. Swappable fixture allows fixtures for other part families to be used.

Skills: Siemens NX, GD&T